After you've tediously typed your essay, thesis, guideline or whatever document that was demanded from you and you've printed out all the pages of said document, the next step from here on out would be binding.

Sure, you could just hand over the pages to your nearest Staples or any other store that provides book-binding services and they'd take care of it for you, but don't you think it would be better if you knew what kind of binding would be best suitable for your work?

All of the numerous types of binding we know today primarily fall under the two main categories: 'Push and Bind' or 'Sort and Bind' which is often known as Thermal Binding. The first category involves punching holes into the stacks of paper and fitting either plastic or metal spirals in them. The latter includes using heat to melt adhesives to bind the pages.

Contents

Types Of Binding For Printing

Both styles of binding have their own merits and demerits and each of them has a limit as to just how many pages they can hold together without necessarily coming undone sooner or later.

Thermal Binding

When you are looking for a way to bind your printed documents, thermal binding is a great option. This type of binding uses heat to fuse the spine of your document to the cover, creating a professional and durable finish. Thermal binding is perfect for presentations, manuals, and other documents that need to look their best.

There are several different types of thermal binding machines on the market, so it is important to choose one that will work best for your needs. If you plan on binding a lot of documents, you may want to consider a machine that has an automatic feeder. This will save you time and effort in the long run.

Once you have chosen the right machine, you will need to purchase thermal binding covers. These come in a variety of colors and styles, so you can choose the ones that best match your document. Make sure to purchase covers that are the right size for your machine; otherwise, you may end up with an uneven finish.

Thermal binding is a process of using heat to adhere a cover to the spine of a document. This method is often used for presentations, reports, and other documents that need to have a professional appearance. There are several advantages and disadvantages of thermal binding that you should be aware of before you decide if this method is right for your printing needs.

The Pros and Cons of Thermal Binding for Printing

Pros:

- Thermal binding creates a clean, finished look for your documents.

- This method can be done quickly and easily, without the need for special equipment or training.

- Thermal binding is extremely durable, so your documents will stay together securely over time.

- You can use thermal binding with a variety of different materials, including covers with different textures and colors.

- Thermal binding is relatively inexpensive, making it a great option for budget-conscious consumers.

Cons:

- Thermal binding can be time-consuming if you have a large number of documents to bind.

- This method requires the use of heat, so there is a risk of damaging your documents if you are not careful.

- You may need to purchase special covers or spines in order to use thermal binding on your documents.

- Thermal binding is not always compatible with all types of printers, so you will need to check compatibility before using this method.

- There is a risk of melting the adhesive if the binding process is not done correctly.

Thermal binding is a great option for many different printing needs, but it is important to weigh the pros and cons before deciding if this method is right for you. If you need help deciding, our team of experts at Printing Services can offer guidance and advice.

Comb Binding

Plastic comb bindings, alternatively known as GBC bindings, are one of the most common - and not to mention, inexpensive - binding options globally. It has a very impressive and high capacity for pages (over 400) and is extremely convenient as you can add, reduce and rearrange the order of the pages even after they have been bound by simply opening the binding.

It is important to mention that the plastic used in comb binding isn't of the highest standards. However, a good alternative to this would be using ZipBinds. Although its carrying capacity isn't as high, you would be enjoying the same benefits of regular comb binding but with better quality plastic.

The Pros and Cons of Comb Binding for Printing

There are a few different types of binding that you can choose from when you are getting your documents printed. Comb binding is one option that you may want to consider. Here are some of the pros and cons of comb binding to help you make your decision:

Pros:

- Comb binding is very affordable, which makes it a great option for those on a budget.

- This type of binding is very easy to do yourself, so you can save even more money by doing it yourself.

- Comb binding gives your document a professional look that other types of bindings (such as stapling) cannot provide.

- This type of binding makes it easy to add or remove pages from your document, which can be very handy if you need to make changes after it has been printed.

Cons:

- Comb binding can be somewhat time-consuming, so it may not be the best option if you are in a hurry.

- This type of binding is not as strong as some other options, so it may not be ideal for documents that will be handled frequently.

Overall, comb binding is a great option for those who want an affordable and professional-looking way to bind their documents. If you don't mind spending a little extra time on the project, then comb binding could be the perfect solution for you.

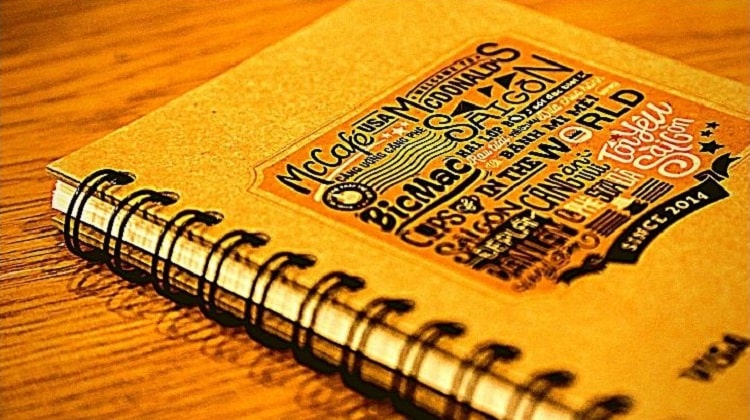

Plastic Coil / Spiral Binding

Now, these guys aren't as cheap as comb bindings, but they don't cost an arm or leg either. There are two types of coils available for this form of binding: plastic and metal. You'll find a lot of crafty notebooks have this sort of cohesion.

This too can bind slightly more than 400 pages. However, the catch with spiral binding is that once it's done, augmentations among pages can be carried out but unlike comb binding, you cannot reuse the same spine and would have to get it redone.

The Pros and Cons of Plastic Coil / Spiral Binding for Printing

As a printing option, plastic coil / spiral binding has its pros and cons. Here are some things to consider before choosing this type of binding for your project:

Pros:

- Allows for pages to lay flat when open, making it easier to read

- Can be used with a wide variety of paper types and sizes

- Relatively inexpensive compared to other binding options

- Durable - can withstand repeated use

Cons:

- May not lie completely flat when closed, depending on the thickness of the document

- Coils can be difficult to insert and remove from the binding machine

- Not as widely available as other binding options

Overall, plastic coil / spiral binding is a good option for those looking for an inexpensive way to bind their documents. It is also a good choice for those who need a durable binding that can withstand repeated use.

Thin Loop Wire Binding (Wire-O Binding)

You'll find that Wire-O Binding is almost indistinguishable from coil binding except that instead of a single loop, it consists of two metal loops. It is more secure than comb and spiral binding and is a great option if you want to be in for the long run.

Precisely because of this, editing your pages wouldn't be impossible but they would certainly be difficult. You cannot make any last-minute alterations without needing a whole new wire, so one ought to make sure that the pages are organized accordingly.

Unlike the other options mentioned above, Wire-O Binding can be used for around 250 sheets. But very much like the others, it offers your pages the liberty of 360-degree rotations.

Perfect Binding

This method of binding is largely used for soft-covered books. It's a little pricier than your average punch and bind alternatives, but it does offer a cleaner finish. There are no wires or holes involved in this sort of binding. Instead, glue is used at the spine once the pages are set in order.

The covers are usually made from cardstock papers that are sometimes laminated. It can bind up to 300 sheets but due to the hardened glue in the spine, the books that undergo perfect binding often face trouble when it comes to laying completely flat on tables.

Case Binding

When it comes to professionalism, you'd want to opt for case binding. Sure, it falls on a costlier spectrum but it would be worth every penny as a long shelf life would be more than promised to you.

For case binding, pages are either sewn and glued to the hardcover, or a metal spine called 'channel' is used to clamp the pages in place before it is glued into position. A total of around 300 pages can be bound together with this procedure.

Saddle-Stitch Binding

This technique involves folding pages on one side and stapling said pages on the fold line on the opposite side. The pages are then sewn together in sections with thread that is usually white, although the color of the thread would hardly matter.

It's the most cost-effective route to opt for, especially when you have to bind around 60 pages more or less. Brochures, magazines, and even comic books are usually bound together with this method! Just because you're more familiar with a specific kind of binding style doesn't necessarily mean that it's the best for you. Before you barge into a store and say that your pages need binding, consider the following - cost, durability, and of course, appearance - and then choose amongst the bindings that best suit the occasion

Tape Binding

Tape binding is a common method of printing. It involves using a tape to hold the paper together while it is being printed. This type of binding is often used for books, magazines, and other publications. Tape binding can be done by hand or by using a machine.

When tape binding by hand, you will need to use a piece of tape that is slightly longer than the width of the paper. Place the tape on the top of the paper, making sure that the adhesive side is facing down. Then, fold the paper in half so that the top edge meets the bottom edge. Next, take another piece of tape and place it over the first piece of tape. Make sure that the adhesive sides are facing each other. Finally, fold the paper in half again and secure the edges with tape.

If you are using a machine to tape bind, you will need to use a binding machine. These machines can be found at most office supply stores. Follow the instructions that come with the machine to bind your documents.

Conclusion for Types Of Binding For Printing

As you can see, there are many different types of binding that can be used for printing. Each type has its own benefits and drawbacks, so it's important to choose the right one for your project. Hopefully this article has given you a better understanding of the different types of binding and how they can be used. Thanks for reading!

Related posts: